Comprehending System Lift Dimensions: Essential for Efficient Lift Service

Wiki Article

Comprehensive Evaluation on Usual Issues and Solutions in Lift Fixing

In the world of lift repair service, a thorough examination of usual issues and their corresponding services is vital to making sure the seamless procedure and safety of these vital vertical transport systems. From the troublesome troubles with elevator doors to the intricate intricacies of electrical breakdowns, a myriad of challenges can plague lift capability (lift breakdown). As we look into the details of elevator maintenance, a thorough understanding of these concerns and the efficient strategies for resolving them becomes a crucial facet of making certain optimum lift efficiencyElevator Door Issues

One of the most typical obstacles run into in lift upkeep is dealing with elevator door malfunctions. The smooth procedure of lift doors is important for passenger safety and efficiency. A malfunctioning door can result in hold-ups, trouble, and also potential risks.Lift door concerns can come from various factors, such as malfunctioning door sensors, misaligned doors, damaged rollers, or concerns with the door driver mechanism. These breakdowns can lead to doors closed or closing correctly, getting stuck midway, or even shutting too promptly, positioning a risk to passengers going into or leaving the lift.

To deal with elevator door breakdowns effectively, maintenance service technicians have to carry out routine evaluations, lubricate moving parts, adjust door timings, and change damaged components without delay. Furthermore, carrying out precautionary maintenance timetables can help determine and fix possible door issues before they escalate. By focusing on elevator door upkeep and quickly addressing malfunctions, structure owners can make certain the reliable and safe procedure of their lifts.

Electric Breakdowns

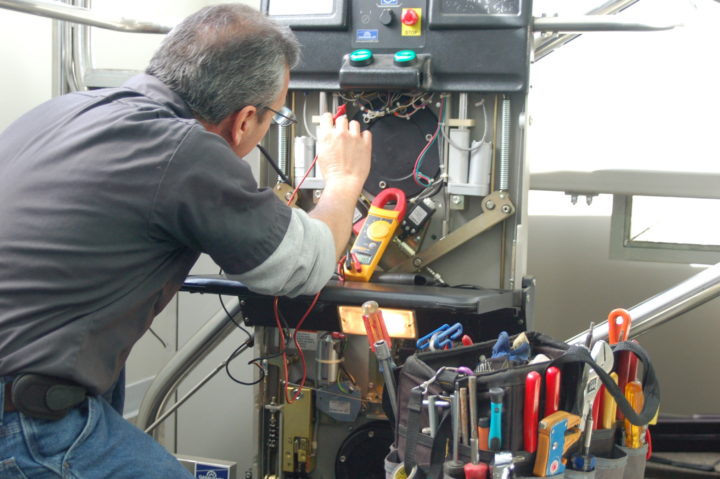

Addressing electrical breakdowns in lifts needs thorough diagnostic evaluations and precise troubleshooting strategies to guarantee the safe and dependable functioning of the lift system. Electrical breakdowns can materialize in numerous means within a lift system, ranging from problems with the control panel, damaged wiring, power supply problems, to issues with interlocks and sensors. When coming across electric malfunctions, it is vital for maintenance employees to comply with a methodical technique. This consists of inspecting the power supply to the lift, checking wiring for any signs of damages or wear, and examining the functionality of crucial components such as the control panel and emergency situation stop button. Using analysis tools such as multimeters and circuit testers can help in pinpointing the origin cause of the electrical malfunction accurately. In addition, making sure that all electrical links are protected and up to code is important in protecting against future malfunctions. By addressing electrical issues without delay and successfully, lift specialists can maintain the safety and efficiency of lift operations.Hydraulic System Issues

In addition, hydraulic pump failures can occur as a result of concerns such as overheating, excessive wear, or lack of proper upkeep. A malfunctioning pump can lead to the lift not having the ability to create sufficient hydraulic stress to operate effectively. Routine assessment, upkeep, and timely replacement of hydraulic parts can prevent these problems and ensure the smooth performance of the lift system. Appropriate training for maintenance personnel on hydraulic system repairing and repair service can also assist in attending to these problems promptly and efficiently.

Control System Glitches

Control system breakdowns can interrupt the smooth operation of lift systems and pose safety dangers if not without delay dealt with. When the control system falls short to interact efficiently with the lift components, it can result in unpredictable movements, unforeseen quits, or full shutdowns.To resolve control system problems, lift repair professionals must conduct extensive diagnostics to identify the origin cause of the issue. By immediately resolving control system malfunctions, lift drivers can make sure the safety and integrity of their systems for passengers and protect against costly downtime.

Safety Features Problems

In guaranteeing the optimum performance of lift systems, vigilance towards the stability of safety functions becomes vital following the recognition and resolution of control system glitches. Security attributes in lifts are developed to stop breakdowns, injuries, and crashes. Resolving safety and security feature concerns quickly can substantially decrease the risk of accidents and enhance the total safety and security of lift procedures.Conclusion

Finally, common issues in lift repair service include lift door concerns, electrical malfunctions, hydraulic system issues, control system problems, and security functions issues. It is critical for maintenance teams to deal with these problems quickly to make sure the efficient and secure procedure of lifts. By carrying out proper upkeep protocols and routine examinations, these concerns can be determined and settled successfully to avoid any type of disruptions in elevator feature.

In guaranteeing the optimal functionality of lift systems, watchfulness towards the honesty of security features ends up being critical complying with the recognition and resolution of control system glitches - lift service company.In verdict, usual issues in lift repair consist of lift door problems, electric malfunctions, hydraulic system issues, control system problems, and safety functions issues

Report this wiki page